Mashiinka jarista mindi laba-wareeg ah oo otomaatig ah

Mashiinka jarista mindi laba-wareeg ah oo otomaatig ah

Ku saabsan slatter laba-laab ah

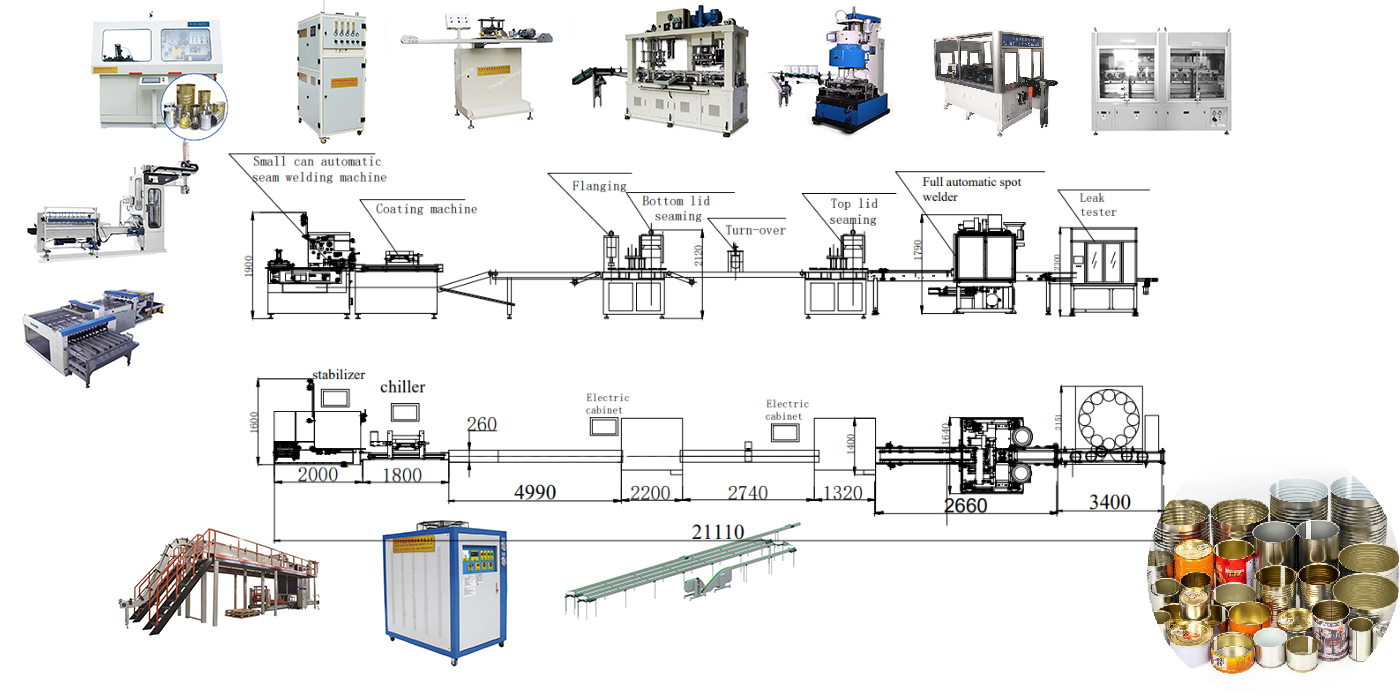

Jeexjeexa laba-jibbaaran waa mid ka mid ah qalabka ugu muhiimsan ee ku jira khadka wax soo saarka qasacadaha 3-xabbo ah. Mashiinka jeexista waxaa loo isticmaalaa in lagu jaro saxanka daasadaha meelaha banaan ee jirka qasacadaha cabbirka saxda ah. Jeexjeexa laba-jibbaaran waa tayo sare leh waana xal ugu fiican warshaddaada baakadaha birta ah.

Si gaar ah loogu talagalay warshadaha cuntada qasacadaysan iyo warshadaha wax soo saarka qasacadaha madhan. Waxa kale oo ay ku habboon tahay in biraha xaashida ah loo jaro cabbirro la mid ah warshadaha kale, waxayna dabooli kartaa shuruudaha adag ee mashiinka alxanka xawaaraha sare leh.

Jeexjeexku wuxuu ka kooban yahay quudiye, xiir, sanduuqa xakamaynta korontada, bamka faakuumka, rarka iyo afeeyaha. Jeexjeexa badan ee shaqeynaya waa kala duwanaansho uu si toos ah u quudin karo, si toos ah u jari karo, si toosan, si toosan loo jari karo, ogaanshaha laba-laablaha ah iyo tirinta koronto-magnetism.

Marka la soo koobo, slitter-ka otomaatiga ah ee laba-laablaha ah wuxuu ku shaqeeyaa habka soo socda:

1. Quudinta Warqadda Tooska ah

2. Gooynta Toosan, Soo qaadida iyo meelaynta, Gooynta Jiifka ah

3. Uruurinta iyo is dulsaarista

Aad bay u adag yihiin, waxay fududeeyaan habaynta fudud, degdega ah ee qaababka kala duwan ee madhan waxayna hubiyaan saxnaan aad u sarreysa. Marka ay timaado kala duwanaansho, saxnaan, isku hallayn iyo xawaaraha wax soo saarka, jajabyadayadu aad bay ugu habboon yihiin soo saarista qasacadaha birta ah.

Halbeegyada Farsamada

| Dhumucda Xaashida | 0.12-0.4mm |

| Dhererka xaashida iyo cabbirka ballaca | 600-1200mm |

| Tirada xariijimaha ugu horreeya ee la jaray | 4 |

| Tirada jarista labaad | 4 |

| Ballaca ugu horreeya ee la jaray | 160mm-500mm |

| Ballaca labaad ee la jaray | 75mm-1000mm |

| khalad cabir | 0.02mm |

| Khalad shaabadaysan | 0.05mm |

| cillad | ≤0.015mm |

| Xawaaraha wax soo saarka ee deggan | 30 xaashi/daqiiqad |

| awood | Qiyaastii 12Kw |

| Aqbalku wuxuu ku salaysan yahay heerka birta ee heerka koowaad ee Baosteel ama heerarka walxaha u dhigma. | |

| Koronto la'aan | Fiilo shan-xagal ah oo AC ah (oo leh saldhig shaqeynaya iyo saldhig ilaalin ah) |

| Danab | 380V |

| danab hal-waji ah | 220V ± 10% |

| Kala duwanaanshaha soo noqnoqda | 49 ~ 50.5Hz |

| Heerkulka | ka hooseeya 40°C |

| Qoyaanka | ka hooseeya 80% |

Macluumaad dheeraad ah. oo ku saabsan qashin-qubka hal mar ah

Gooynta xaashida birta ah waa saldhigga ugu horreeya ee xariiqda samaynta qasacadda.

Waxaa loo isticmaalaa in lagu jaro xaashida birta ah ama xaashida birta aan daxalka lahayn sida qaybaha jidhka ee cabbirka loo baahan yahay ama xariijimaha loogu talagalay dhammaadka qasacadaha. Jeexjeexa laba-jibbaaran ama jeex-jeexa hal-jibbaaran waa kuwo la isticmaali karo, sax ah oo adag.

Mashiinka goynta hal-halka ah, wuxuu ku habboon yahay kala qaybinta iyo jarista xariijimaha, mashiinka goynta laba-geesoodka ahna, waa jarista toosan oo leh goyn toosan. Marka mashiinka goynta tinplate uu shaqeynayo, jarista sare iyo jarista hoose waxay ku wareegayaan labada dhinac ee xaashida birta ee daabacan iyo kuwa lacquered, tirada jarista jarista waxay ku salaysan tahay tirada xariijimaha iyo qaababka madhan. Masaafada u dhaxaysa jarista kasta waa mid fudud oo degdeg ah in la hagaajiyo, sidaa darteed nooca mashiinka goynta tinplate waxaa sidoo kale loogu yeeraa mashiinka goynta gang ama mashiinka goynta gang. Jartaha carbide-ka ayaa diyaar u ah sameeyaha qasacadda.

Kahor mashiinka jarista laba-geesoodka ah ama mashiinka jarista hal-geesoodka ah, quudiyaha xaashida ee otomaatiga ah waxaa lagu qalabeeyay inuu nuugo oo uu gudbiyo saxanka birta ah isagoo nuugaya saxanka oo leh nidaam neef-mareen ah iyo qalab ogaansho xaashi laba-geesood ah. Ka dib jarista, ururiyaha iyo qalabku si toos ah ayay u soo saari karaan, wareejinta u dhaxaysa alxanka gooya iyo alxanka qasacadaysan ayaa sidoo kale la heli karaa.

Xawaaraha sare iyo walxaha khafiifka ah waxay u baahan yihiin saxnaan sare iyo dusha sare ee dhalaalaya. Go'yaasha si joogto ah ayaa loo hagaa. Gooyayaashu waxay hubiyaan in xaashi siman oo ammaan ah, xariijin iyo gaadiid madhan. Gooyooyinka hal-go'an waxaa lagu dhammayn karaa hawlgal jaritaan labaad; sidaa darteed maalgashiga gooyooyinka hal-go'an waa maalgashi aad u qiimo badan haddii wax soo saarka go'an la qorsheeyay in la kordhiyo. Si fudud loo dayactiro oo loo shaqeeyo. Gooyooyinka ama si fudud loo jaro go'yaasha. Waxaa laga heli karaa saxanka birta ama go'yaasha aluminiumka.