Khadka wax soo saarka qasacad wareega wareegsan ee 10-25L ee otomaatiga ah

Khadka wax soo saarka qasacad wareega wareegsan ee 10-25L ee otomaatiga ah

Xalka loogu talagalay baaldiyada birta ah

Baaldiyada koonikada ee birta ah waxay leeyihiin is-ururin, cimri dherer, iyo dahaar gaar ah sida epoxy-phenolic si ay u ilaaliyaan iska caabbinta daxalka, waxaana loo isticmaalaa warshadaha sida rinjiga, kiimikada, cuntada, iyo baakadaha dawooyinka.

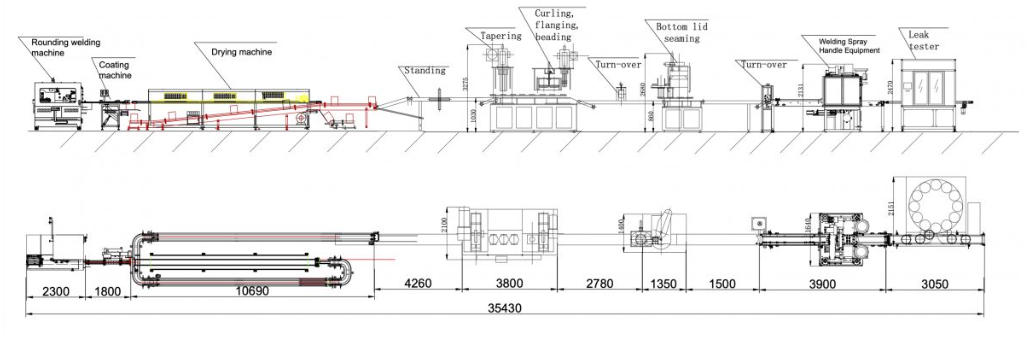

10- khadka wax soo saarka baaldiyada birta ah

Tani waxay samayn kartaa khadka wax soo saarka waaloogu talagalay wax soo saarka otomaatiga ah of Baaquli koonka ah oo ah 10-25L,

kaas oo ka koobansaddex saxan oo bir ah: jirku waa la jari karaa, hoos buuna u dabooli karaa. Qasacaddu waa kooniye.

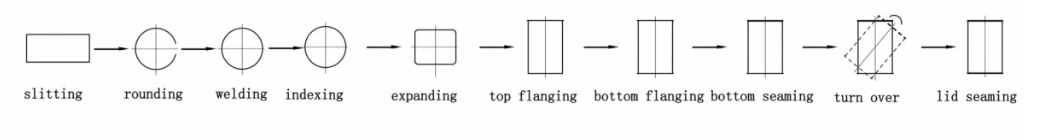

Socodka farsamada:

1. Goynta xaashida qasacadda si ay u madhanto

2. Wareegga iyo Alxanka

3. Dahaarka gudaha iyo dibadda (dahaarka budada gudaha iyo dahaarka dibadda)

4. Qallajinta & Qaboojinta gaarsiinta

5. Qaab-dhismeedka Koonikada & Ballaarinta

6. Flanging, Curling, iyo Beading

7. Quudinta daboolka hoose

8. Tolmo

9. Soo jeesashada

10. Alxanka iyo dahaarka dhegaha iyo qalabka cuntada lagu xidho

11. Tijaabada daadinta-baakadka

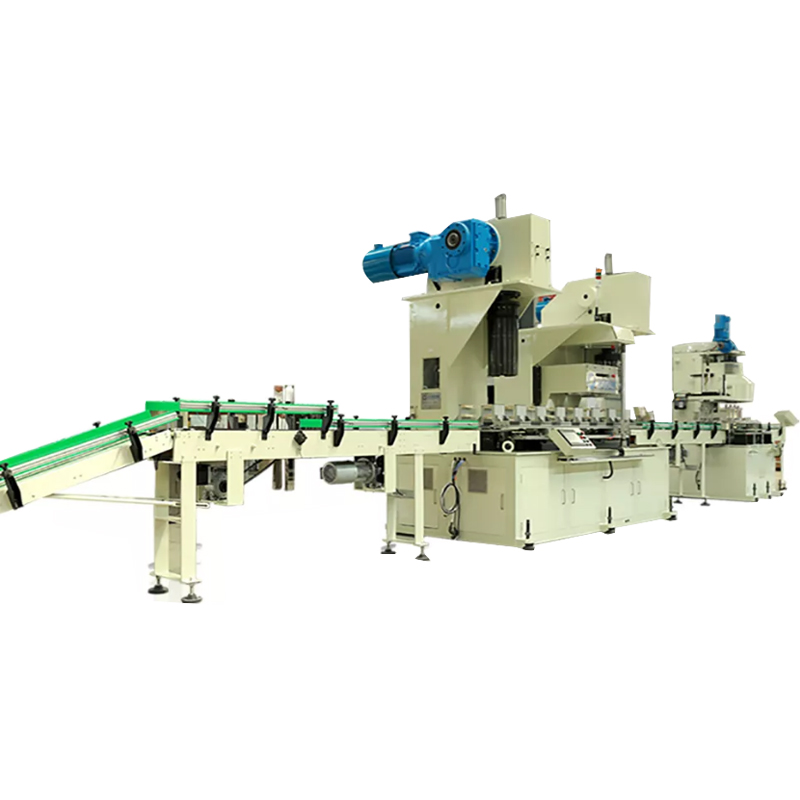

Khadka wax soo saarka qasacad wareega oo otomaatig ah

Tani waxay samayn kartaa khadka wax soo saarka waaloogu talagalay wax soo saarka otomaatiga ah of Baaquli koonka ah oo ah 10-25L,

kaas oo ka koobansaddex saxan oo bir ah: jirku waa la jari karaa, hoos buuna u dabooli karaa. Qasacaddu waa kooniye.

Socodka farsamada:

1. Goynta xaashida qasacadda si ay u madhanto

2. Wareegga iyo Alxanka

3. Dahaarka gudaha iyo dibadda (dahaarka budada gudaha iyo dahaarka dibadda)

4. Qallajinta & Qaboojinta gaarsiinta

5. Qaab-dhismeedka Koonikada & Ballaarinta

6. Flanging, Curling, iyo Beading

7. Quudinta daboolka hoose

8. Tolmo

9. Soo jeesashada

10. Alxanka iyo dahaarka dhegaha iyo qalabka cuntada lagu xidho

11. Tijaabada daadinta-baakadka

Faa'iidooyinka mashiinka sameynta baaldi koonikada ah:

1. Qaab bir ah oo culus oo lagu dhejiyay dahaadh bir ah oo aan miridh lahayn oo lagu xidhay qaab-dhismeedka tuubada taasoo ka dhigaysa mishiinku mid waara, deggan oo lagu kalsoonaan karo.

2. Nidaamka gudbinta farsamada ayaa ka dhigaya inuu shaqayn karo inta uu nool yahay iyadoo dayactir yar la sameynayo.

3. Isku-darka laalaabka hore ee laalaabka, laalaabka, iyo laalaabka geesaha.

4. Naqshad yar ayaa yareysa oo badbaadineysa booska qiimaha leh.

5. Hawlgalku waa mid si buuxda otomaatig ah u shaqeeya oo leh hufnaan iyo awood sare.

6. Mashiinkani wuxuu samayn karaa cabbirro kala duwan oo ah qasacadaha saxanka daasadda ah isagoo beddelaya qalabka.

7. Xakamaynta PLC iyo is-dhexgalka shaashadda taabashada ee saaxiibtinimo leh ee HMI si loo fududeeyo hagaajinta.

8. Nidaamka ogaanshaha cilladaha wuxuu ka ilaaliyaa mashiinka waxyeelada.

9. Nidaamka saliidaynta otomaatiga ah *Qalalaasaha otomaatiga ah

10. Mashiinkani wuu kaligiis shaqayn karaa ama waxaa lagu dari karaa khadkaaga hadda jira.

Mashiinka Sameynta Baaldiga Birta ee Shiinaha waxaa loo isticmaalaa in lagu sameeyo baaldi bir ah oo wareegsan oo 10-25L ah, foosto, foosto, baaldi, sida rinjiga, saliidda, baaldiyada xabagta. Haddii aad rabto inaad sameyso cabbirro kala duwan oo foosto noocaas ah, waxay u baahan tahay oo keliya inaad beddesho qaababka mashiinnada. Cabbirka baaldiga waxaa loo habeyn karaa iyadoo loo eegayo baahiyahaaga.

Habka hawlgalka

▶ Marka hore dhig agabka jirka ee qasacadda la jarjaray miiska quudinta mashiinka alxanka iska caabbinta otomaatiga ah, ku nuug nuugayaasha faakiyuumka, meelaha banaan ee qasacadda u dir duubaha quudinta mid mid. Iyada oo loo marayo duubka quudinta, saxanka keliya ee madhan ayaa la siiyaa duubka wareegsan si loo sameeyo habka wareejinta.

▶ Kadib waxaa lagu quudin doonaa habka sameynta wareegsan si loo sameeyo wareegsan. Jidhka waxaa lagu shubayaa mashiinka alxanka iska caabbinta waxaana la sameeyaa alxanka ka dib marka la meeleeyo saxda ah.

▶ Ka dib alxanka, jirka qasacadda waxaa si toos ah loogu shubaa mashiinka dahaadhka ee wareega ee loogu talagalay dahaarka dibadda, dahaarka gudaha ama dahaarka budada gudaha, taasoo ku xiran baahida kala duwan ee macaamiisha. Waxaa inta badan loo isticmaalaa in laga hortago in xariiqda tolmada dhinaca ay ku dhacdo hawada iyo miridhku.

▶ Jirka qasacadda waa in la geliyaa foornada qalajinta ee induction-ka si uu u qalalo haddii uu yahay dahaarka gudaha ama dahaarka budada gudaha. Inta ka horreysa qalajinta, waxaa lagu quudin doonaa qalabka qaboojinta si loo sameeyo qaboojin dabiici ah.

▶ Jirka qasacadda la qaboojiyey ayaa markaa lagu shubaa mashiinka isku-darka baakadaha koonikada ah, jirka qasacaddana wuxuu ku jiraa xaalad toosan oo dhex mareysa qalabka koontaroolka toosan.

▶ Hawlgalka ugu horreeya waa ballaarinta koonka ee jirka qasacadda. Marka jirka qasacadda uu joogo meeshiisa, saxaaradda kor u qaadista jirka qasacadda oo ay maamusho matoor servo ah, jirka qasacaddana waxaa saxaaraddan kor u qaadaysa u diraa caaryada koonka ee ballaaran si ay u samayso koonka oo ballaara.

▶ Tallaabada 2aad waa in la sii kala furfuro Tallaabada 3aad waa in la kala furfuro. Qaabka sare waxaa lagu dhejiyaa jirka mashiinka, qaabka hoosena, kaas oo ku rakiban CAM, wuxuu dhammaystirayaa kala furfurka iyo kala furfurka marka CAM-ka la saaro. Tallaabada 4aad waa in la kala furfuro.

▶ Ka dib marka la dhammeeyo afarta tallaabo ee kor ku xusan, marka daboolka hoose uu ogaado jirka qasacadda soo socda, waxay si toos ah u quudin doontaa hal dabool hoose ilaa sare ee jirka qasacadda, ka dibna jirka qasacadda iyo daboolka hoose labadaba waxaa lagu xiri doonaa madaxa mashiinka tolida si loo sameeyo tolida otomaatiga ah.

▶ Ka dib marka la tolo qaybta hoose, waxaa lagu shubaa mashiinka alxanka lugaha dhegaha oo laba jibbaaran, iyada oo loo marayo tusmada tolmada dhinaca ee otomaatiga ah, rarista gudbiyaha kamarada, jebinta rinjiga farsamada, sidoo kale waxaa ku qalabaysan dhegaha oo si otomaatig ah u gariira saxanno, dhammaystir shaqada alxanka saxda ah ee baaldi koonka ah.

▶Kadib, baaldigu wuxuu ku habboon yahay sameynta iyo rakibidda si otomaatig ah si loo dhammeeyo isku-dubaridka gacanta.

▶ Ugu dambeyntii, qasacadda la dhammeeyay waxaa loo gudbinayaa xarunta tijaabada daadinta otomaatiga ah iyadoo la adeegsanayo qalabka gudbiyaha.

Iyada oo loo marayo tallaabada saxda ah ee lagu ogaanayo isha hawada, alaabada aan u qalmin waa la tijaabin doonaa oo la siin doonaa aagga hagaajinta. Baakadaha u qalma ayaa imaan doona miiska baakadka si loogu xiro baakadaha ugu dambeeya.

Halabuurka qalabka ee qasacadaha wareegsan ee khadka wax soo saarka otomaatiga ah

| Jarjaridda ugu horreysa (ballaca ugu yar) | 150mm | Jarjaridda labaad (ballaca ugu yar) | 60mm |

| Xawaaraha (xabbad/daqiiqad) | 32 | Dhumucda xaashida | 0.12-0.5mm |

| Awood | 22kw | Danab | 220v/380v/440v |

| Miisaanka | 21000kg | Cabbirka (L*W*H) | 2520X1840X3980mm |

| Moodel | CTPC-2 | Danab & Soo noqnoqoshada | 380V 3L+1N+PE |

| Xawaaraha wax soo saarka | 5-60m/daqiiqo | Isticmaalka budada | 8-10mm & 10-20mm |

| Isticmaalka hawada | 0.6Mpa | Ma kala duwanaan karaa jirka? | D50-200mm D80-400mm |

| Shuruudaha hawada | 100-200L/daqiiqo | Isticmaalka Awoodda | 2.8KW |

| Cabbirka mashiinka | 1080 * 720 * 1820mm | Miisaanka guud | 300kg |

| Kala duwanaanshaha soo noqnoqda | 100-280HZ | Xawaaraha alxanka | 8-15m/daqiiqo |

| Awoodda wax soo saarka | 25-35 Qasacadood/daqiiqad | Dhexroorka qasacadaysan ee la dabaqi karo | Φ220-Φ300mm |

| Dhererka qasacadaysan ee khuseeya | 220-500mm | Waxyaabaha la dabaqi karo | Tinplate, oo ku salaysan bir, saxan Chrome ah |

| Dhumucda walxaha lagu dabaqi karo | 0.2 ~ 0.4mm | Dhexroorka silig naxaas ah oo la dabaqi karo | Φ1.8mm, Φ1.5mm |

| Biyaha qaboojinta | Heerkulka: 12-20℃ Cadaadis:>0.4Mpa Socod: 40L/daqiiqo | ||

| Awood guud | 125KVA | Cabbirka | 2200*1520*1980mm |

| Miisaanka | 2500Kg | Budada | 380V ± 5% 50Hz |

| Kala duwanaanshaha dhererka qasacadaha | 50-600mm | Kala duwanaanshaha dhexroorka qasacadaha | 52-400mm |

| Xawaaraha rullaluistemka | 5-30m/daqiiqo | Nooca dahaadhka | Dahaarka duuban |

| Ballaca xabagta | 8-15mm 10-20mm | Sahayda ugu weyn & culayska hadda jira | 220V 0.5 KW |

| Isticmaalka hawada | 0.6Mpa 20L/daqiiqo | Cabbirka Mashiinka & Miisaanka saafiga ah | 2100*720*1520MM300kg |

| Awoodda gubaha | 1-2KW | Xawaaraha kululaynta gubi | 4m-7m/daqiiqo |

| Dhexroorka qasacad yar oo ku habboon | Φ45-Φ176mm | Dhexroorka qasacad weyn oo ku habboon | Φ176-Φ350mm |

| Dhererka qasacadaysan | 45mm-600mm | Biyaha qaboojinta | >0.4Mpa, 12-20℃,40L/daqiiqo |

| Isticmaalka hawada | ≥50L/daqiiqo>0.5Mpa | ||

Nidaamka Isku-darka Daasadaha Jirka ee Tooska ah

| Awoodda wax soo saarka | 25-30cpm | Kala duwanaanshaha Can Dia | 200-300mm |

| Dhererka qasacadaysan ee kala duwan | 170-460mm | dhumucdiisuna waa | ≤0.4mm |

| Awood guud | 44.41KW | Cadaadiska nidaamka neef-mareenka | 0.3-0.5Mpa |

| Cabbirka qaadaha toosan ee jirka | 4260*340*1000mm | Cabbirka mashiinka isku-darka | 3800*1770*3200mm |

| Cabbirka kaarbinetka korontada ku shaqeeya | 700 * 450 * 1700mm | Miisaanka | 9T |